Soul of the Home

In Finland, masonry heaters are known as “heart of the home,” and in Russia it’s “soul of the home,” reflecting the importance they have in people’s lives.

Alex Chernov with one of his masonry heater installations – each is custom designed. An average home can be heated with two high-efficiency firings a day. Photos Courtesy Alex Chernov / Stovemaster.

Alex Chernov brought a little piece of good old-fashioned know-how from his Ukrainian birthplace when he immigrated to Canada in 1999.

As is traditional in Ukraine, the heat source in his childhood home was a masonry heater. “Likely 70 per cent of homes in Eastern Europe and Russia use masonry heaters,” says Chernov, who worked as a mason in Europe. Here in Canada, when he built a new house for himself, his wife and her parents a few years ago, he researched masonry heaters further. As a result he met up with Igor Kuznetsov, a Russian engineer and mason who has been working since the mid-1960s on developing more refined designs. The two formed a partnership in 2002, and Chernov’s company, Stovemaster, was born.

What, you may ask, is a masonry heater? In use for centuries throughout much of the world, the concept is fairly simple: efficient combustion of a fuel load (usually firewood) in a chamber, followed by a long exit channel through the masonry. As exhaust gases pass through the channel, the heat is retained in the stove’s large masonry mass. The heat gradually radiates back out over a period of twelve to twenty-four hours. This differs from metal wood stoves, which produce heat only while they are burning, and from common North American fireplaces, which, while built from similar materials to masonry heaters, offer very low or even negative efficiency.

Brenda Dolling is a member of Whole Village, a small community of like-minded people who both live and operate an organic farm on seventy-seven hectares in north-west Caledon. Committed to sustainability, the group went to great lengths to ensure energy efficiency when they built a 15,000-square-foot communal living facility named Greenhaven.

Though the building is heated by a geothermal system, Dolling says “We still needed quite a bit of electricity to run the pumps, and we wanted to get away from that.”

Two years ago, Stovemaster was engaged to design and install a masonry heater. How has it worked out? “We absolutely love it,” Dolling says. “It’s probably one of the best features of our building, in terms of energy efficiency. We’ve been surprised at how little wood it burns. It also heats more area than we expected – all the common space in the building, which is about 6,000 square feet. We use wood gathered here on the farm.”

Given the bulk of a masonry heater, which needs to be built on a concrete foundation, it’s easiest to install them during new construction. However, says Chernov, “We’ve also done a lot of retrofits – about half our business.” As the units produce radiant heat, an open-concept floor plan can be beneficial, but Chernov says “the quality of insulation is more important. In most houses, if the insulation is good and you leave the interior doors open, you’ll have no problem.”

Though heating is the most common purpose, the units can also be outfitted with cook tops, baking and pizza ovens, an open fireplace, heated benches or even as a boiler or hot water source. The company has also completed a number of special projects, such as commercial pizza ovens, outdoor bake houses and saunas. Each installation is custom-designed to suit the client’s needs, based upon a set of basic principles.

With efficiency estimated at between 70 to 85 per cent, an average home can be heated with only two firings a day, lasting two to two-and-a-half hours each. At Whole Village, they’re finding it better than that. “Usually, it only needs one firing a day. If it’s really cold out, like minus ten, we’ll put another armful on at night,” Dolling says.

Chernov installed this heater at Caledon’s Whole Village two years ago: “We’ve been surprised at how little wood it burns. It all also heats more than we expected.” Photos Courtesy Alex Chernov / Stovemaster.

Chernov points out some other advantages. “They’re also much safer. There are no hot surfaces like with metal stoves. And because they burn so efficiently, they produce no creosote and almost no wood smoke emissions. The possibility of a chimney fire is eliminated.” Efficient burning also means low ash production – about one per cent of wood, so ashes only need to be emptied every three or four days.

As to cost, Chernov points out that “The finish is a big part of the price. In Europe these units are fairly utilitarian, but here people are used to nice fireplaces.” Bearing that in mind, prices start at around $7,000, though “with nice options it’s typically between $10,000 and $15,000.” Installation of the foundation and chimney are extra. In addition, for those times owners are away or otherwise have to miss a firing, a back-up system is necessary. “Usually we add baseboard heaters,” says Chernov.

The Whole Village project was “more than $10,000,” but Dolling sees the cost as reasonable. “It may seem expensive, but if you consider the amount of material, and the engineering that goes into it, it’s not that bad. An average fireplace must cost something close to that, and the efficiency is terrible.”

Rising energy costs may well make masonry heaters a more common sight in Canadian homes. “We’re sold,” says Dolling. “We recommend it to everyone who comes in, and are considering the possibility of another unit for our farmhouse.”

Stovemaster built eleven heaters and four bake ovens last year. “Interest has been steady over the last couple of years,” Chernov says. “Historically, Canada is a wood-burning country, and right now people are searching for a better way. The main thing is, this is a well-developed technology, proven in Europe, that we can use now.”

In Finland, masonry heaters are known as “heart of the home,” and in Russia it’s “soul of the home,” reflecting the importance they have in people’s lives. Would you say the same for the furnace in your basement?

Related Stories

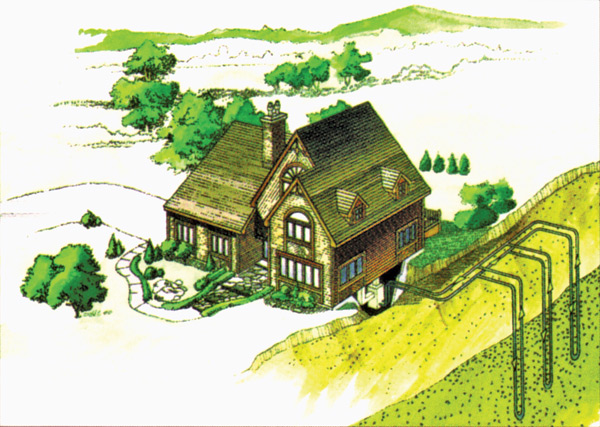

Geothermal. Earth Energy.

Sep 15, 2008 | | Back IssuesCLEAN, RENEWABLE AND FREE. Call it what you like, with the support of large grants and rebates for installation, Headwaters residents are pulling heat from the ground.